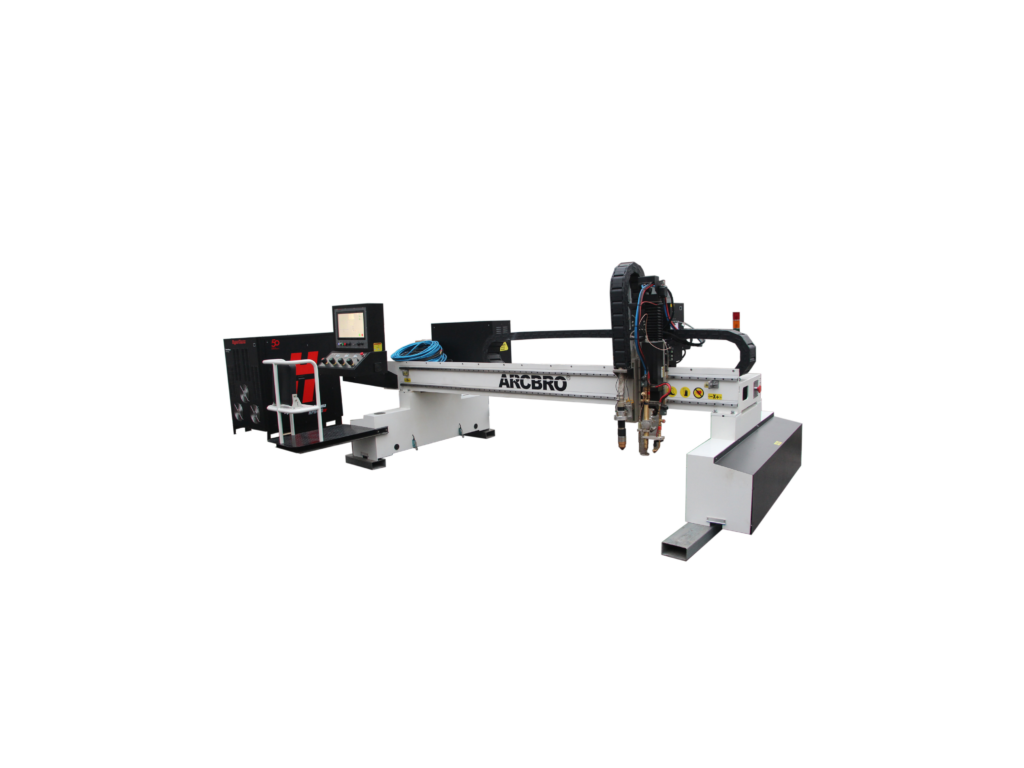

X-Master

CNC Gantry High Definition Plasma Cutting Machine

Standard Features 1:

- Effective cutting area: 3000*6000mm, can be extended

- Both plasma and flame mode (with Auto-ignition)

- Plasma cutter: Hypertherm XPR series / Thermal Dynamics UC series

- Hypertherm CNCs system / Thermal Dynamics ICNC system (built-in THC)

- SIGMA BHQ software (Small hole technology nesting software)

- Japan Panasonic servo motor, dual drive mode

- Silver-plated linear guide rail plus 38kg steel rail

Standard Features 2:

- Effective cutting area: 3000*6000mm, can be extended

- Both plasma and flame mode (with Auto-ignition)

- Plasma cutter: Arcblitz (LH 270)

- Shanghai FangLing system F7600

- Shanghai FangLing THC

- SIGMA NEST software

- Mitsubishi servo motor, dual drive mode

- Silver-plated linear guide rail plus 38kg steel rail

High definition plasma cutting is a new technology that has been around for less than a year. It is completely different from traditional plasma cutting.

The high definition cutting completely eliminates the requirements of the craftsmanship of the workers. It classifies and integrates all the factors affecting cutting.

It does not require manual intervention by the operator and automatically ensures the quality of the bolt holes.

It narrows the gap with the quality of laser perforations, allowing the plasma cutting process to be used in many previous jobs that require laser cutting systems.

- SPECS

- DATA SHEETS

| Cutting mode | high definition plasma cutting for true hole technology |

| Effective cutting area | Width 2.5- 5m Length minimum 6m (Length and width can be optional |

| Number of torches | a set of automatic plasmas, a set of automatic flames |

| Drive mode | Longitudinal – 1000Wx2 large inertia; horizontal – 750Wx1 large inertia; lifting 400 W; Japan Panasonic servo system, dual drive mode |

| Reducer | 1:40 Nidec |

| Vertical orbit | Silver 38 kg rail on the longitudinal rail; silver (silver) 20 linear rail in the horizontal direction; |

| Rack and pinion specifications | 2-mode helical tooth |

| Cutting thickness | 0 – 45 mm perforation cutting (plasma); flame cutting thickness 0-200mm (for thicker optional |

| Small hole technology nesting software | Sigma nesting / lantek / pronest |

| Running speed | 0-15000mm/min |

| positioning accuracy | ±0.08 mm |

| Tolerance | ≤0.3mm |

| Machine input voltage | 220V single phase |

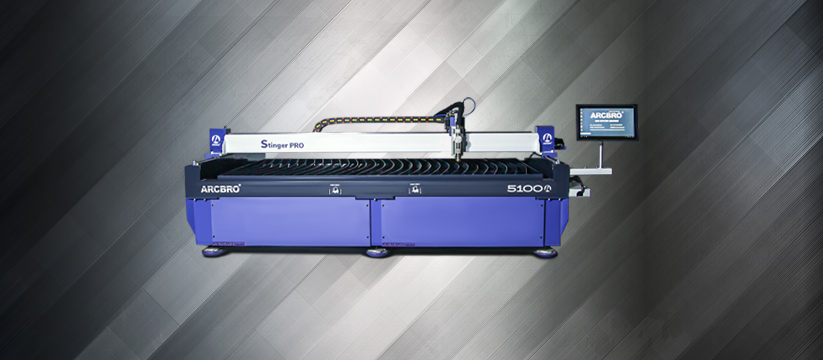

STINGER PRO 5100 Brochure

STILL HAVE QUESTIONS? CONTACT US NOW!

CHOOSE A PRODUCTS

Choose the one that best meets you in all range of ArcBro professional CNC cutter!

LEARNING CAMPUS

View ARCBRO learn campus online to learn the machines before you get them.