ARCBRO Nesting Software

ARCBRO Nesting software

Start page nesting software includes several major part of the software:

- The CAD/computer aided design

- The CUT/cutting

- The current

- The tool

CAD/computer aided design: in this section you can import an existing project or create a new. , compatible file included with the DXF, DWG,. D is the file suffix. (S.I. Engineering properties of format)

The CUT/cutting: this part includes the production of parts and nesting, and finally completed a cutting of the product.

Current: the current menu displays the current working file

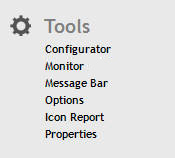

The tool:

Configuration program: management major software Settings (such as: language Settings).

Software Monitor: open the Monitor panel can check parts related parameters.

News article: in the user interface under direction show relevant information.

Options: software page layouts and other Settings.

Parts report: generate a report for printing parts.

Properties: a selected part appears in the form of a list of attributes.

Change the system default language:

Configuration program>The “main” label>Language (double click)>Select the language>confirm

The flow chart:

CAD/computer aided design CAM/computer aided manufacturing POST PROCESSOR/rear handler

·The new design ·Drag and drop from the parts ·Option is set

·By drag and drop from the library to nesting import a part ·Create parts processing

component library a parts ·Automated material handling program

or graphics exchange file ·Create the cutting path ·Save each product parts

(DXF) to import ·Create a board report processing program

·Parts, graphic files (DWG), ·save the result

graphics exchange file (DXF)

and other format file import:

file > import

·Has been created and save

the parts

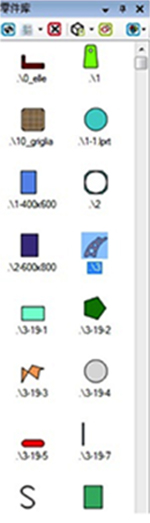

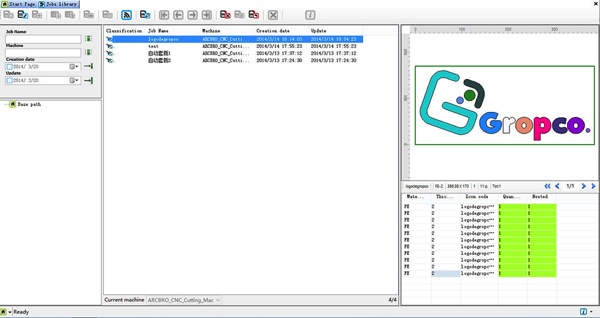

Parts library:

Home page click open parts library.

Generated and saved before parts library contains all parts.

Through parts library, every parts of the relevant data visual image, and can be modified.

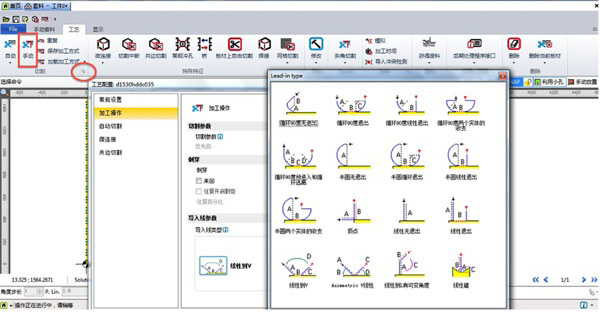

The introduction of line selection:

When you use the local cutting parameters in the process of manual or automatic process change into line feature, click on the “process” under the label “cutting” the context menu for the small red circles (Shown below)

Select in the table to the introduction of the line. Choosing the introduction of line parameters will be intuitive appears on the right side of the window. After finish to modify the corresponding parameters, click the “ok”, the options window will close, back to process the page.

Automatic nesting, automatic conversion:

Basic contains software:

·MICROSOFT PARTNER

·Advanced GUI

·ZERO training

·Import DXF™/DWG™

·Cad [Drag & Drop]

·Cad [ONE CLIC] Tecnology

·[Drag & Drop] nesting

·Switch Multi Machine controll

·Manual Nesting

·Auto Nesting

·Auto CUT Tecnology

·Nesting [ONE CLIC] Tecnology

·Nesting Report

Saving material

The nesting algorithm allows to save a lot of scrap.

The use of nesting is very easy and doesn’t need many settings to get the best result.

The nesting can work with standard sheets stocked in the ware- house and/or with scraps obtained from previous processing.

Trim calculation:

Sheet metal can according to the linear shape clip in order to optimize more than expected.

One Click [SUPPORT]

One Click support is a direct connection through the web with ours operators. 24 hours quickly solve problems encountered in the process of operation for you.

Minimum hardware Settings:

• CPU Core™ 2 or similar

• Hard disk 160 GB (2GB Free)

• 2 Gb RAM

• Video Card with 64 Mb Ram memory

• DVD ROM 16x

• Monitor 17” (1024X768)

• Mouse 3 buttons with wheel

• USB port for USB License Key

COM Port RS232 (9 pin) *if the pc need the transmission with cable to the machine.

The client operating system:(HOME version are not supported)

• Microsoft® Windows XP® Professional SP3 (32bit or 64 bit)

• Microsoft® Windows Vista® Business e Ultimate (32bit or 64 bit)

• Microsoft® Windows 7® Professional e Ultimate (32bit or 64 bit)

Compatible format:

.DXF, .DWG, .SAT, .IGS, .STP, .MODEL, .CATPART, .PRT, .IPT, .SLDPRT, .BXF, .NC1, .NC2, .DPR, .DIN, .GEO, .LOS, .MEC, .CP, .MODEL, .IAM, .SLDPRT,.SLDASM.CATPart, .CATProduct, .SAB, .ASAT, .ASAB, .EXP, .SESSION