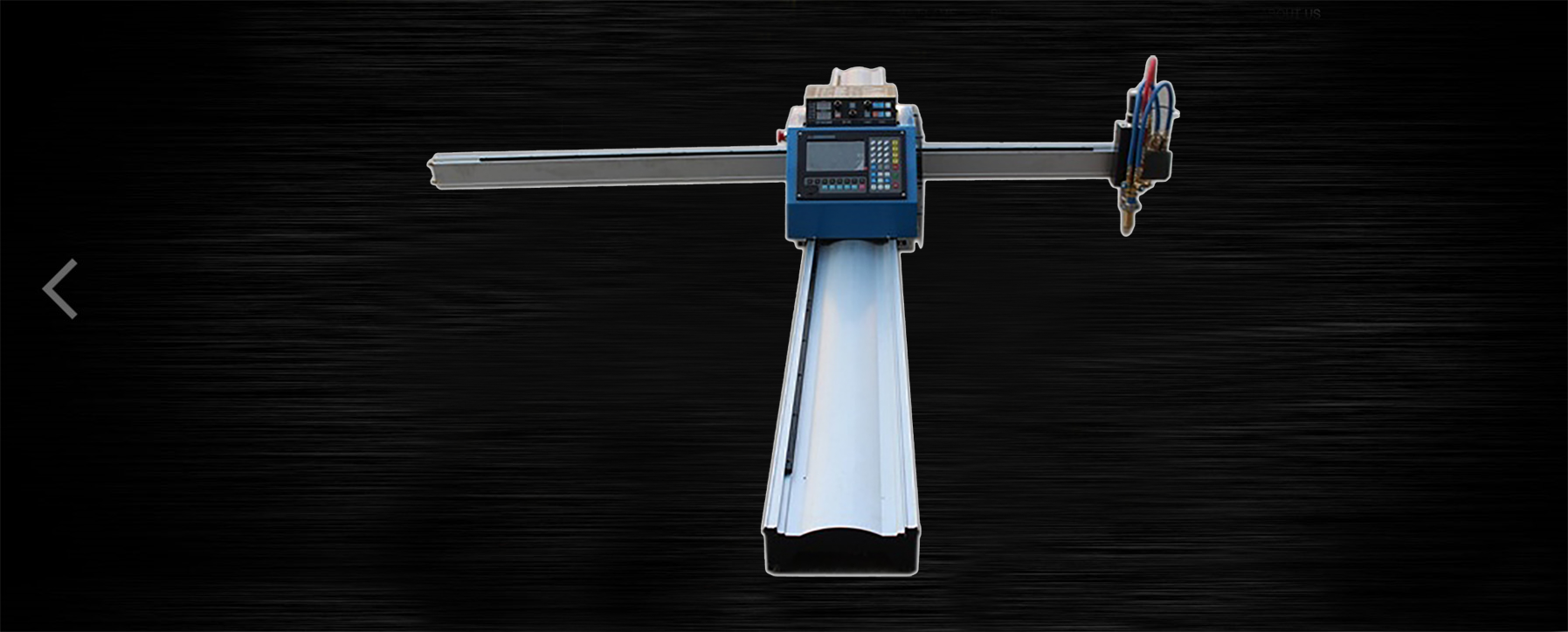

ARCBRO Stinger Bench Plate Cutter

Overview

< Scout | Standard Features >

- The lightest plasma cutting machine! Only 98Kg!

- It is new update version based on the Scout 1, and if you do the flame CNC cutting only, Scout 2 will be the best choice.

It is also with the Libellula software with auto nesting.

ArcBro Scout Demo video:

https://vimeo.com/198651413

https://vimeo.com/208847570 - Oxyfuel gas cutting process involves preheating the base metal to a bright cherry red, then introducing a stream of cutting oxygen which will ignite and burn the metal. Possible fuel sources include propane and acetylene.

- The ArcBro-Scout standard cutting area is 1,200X2,000mm

Max cutting area can reach 1,500X15,000mm

Oxy-Fuel and Plasma cutting

Compact, Light weight, easy to use and set up

It can cut any figures unless you can design using Auto CAD

Be used directly on the plate to be cut or mounted on a cutting table

Motorized torch riser allows torch adjustment from

Specifications

|

Technical Parameters |

|

|

Input Voltage |

110V/220 V |

| Frequency | 50 Hz/60Hz |

| Input Power | 180 W |

| Display | LCD 7 ” |

| Effective Cutting Range | Y-Axis:

2.0m,2.5m,3.0m,3.5m,4.0m…… 14.5m,15m X -Axis: 1.2m,1.5m(see note 1) |

| Moving Speed | Flame cutting :0 –1000 mm/min

Plasma cutting :0–6000mm/min |

| Cutting Thickness | Flame cutting : 5mm – 150 mm

Plasma cutting : MIN Cutting thickness 2mm ; Depends on plasma power source capacity |

| Control accuracy | ±0.5 |

| Cutting precision and quality | Plasma: According to JB/T 10045.4-1999

Flame: According to JB/T 10045.3-1999 |

| Mode of Cutting | Flame or Plasma |

| Combustive Gas | Oxygen |

| Combustive Gas Pressure | Max 1.5 Mpa |

| Fuel | Acetylene – Propane – Methane – Gasoline

(see note 3 and note 4) |

| Fuel Pressure | Max 0.1 Mpa |

| Cutting Software |

FastCam |