2019 Nov Technology Exchange for VWI in Germany

ArcBro’s technicians went to the JAVAC plant in Germany to perform machine testing and technical exchanges with technicians at Javac, Victor, and libellula. This exchange was based on ArcBro’s fine plasma cutting machine “X mark” and was tested in a comprehensive manner around new technologies such as plasma fine cutting and vented water injection (VWI) cutting.

Vented Water Injection (VWI) Test

This patent pending process features a vented N2 plasma and an H2O shield. Edges are square, angularity is reduced and surface finish is excellent on non ferrous materials, especially aluminum. The video is a demo of X mark Vented Water Injection cutting.

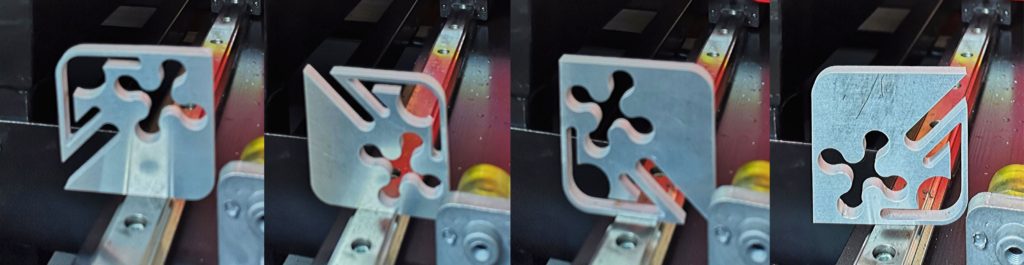

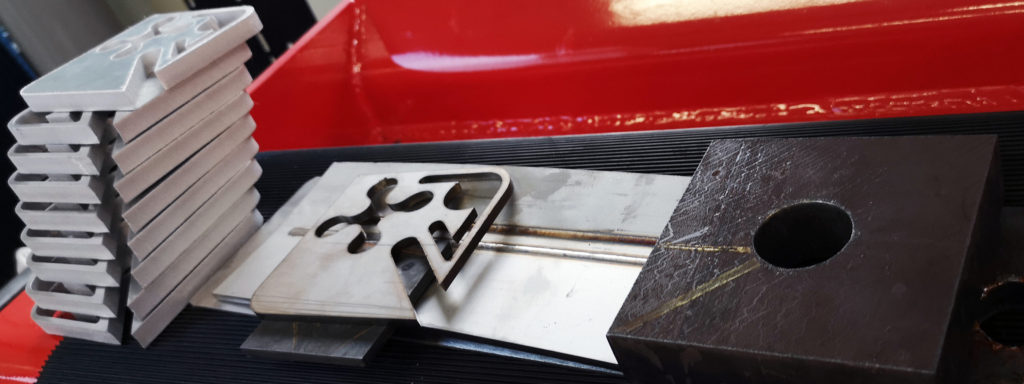

Verticality & flatness test

Aluminum (left), stainless steel (middle), carbon steel (right)

The cut stainless steel, aluminum and carbon steel have a smooth and refined cross section.

This quality of cutting undoubtedly reduces the cost of secondary processing after plasma cutting. And X Mark has a faster cutting speed , and a higher consumable life. The leap of X Mark’s comprehensive operational capability is undoubtedly a disruptive development in the field of plasma cutting.

“The development direction of plasma industrial cutting is bound to be fine cutting, and how to use fine cutting to reduce production costs and increase productivity. This is recognized by everyone present.” ArcBro’s technician Chao said.