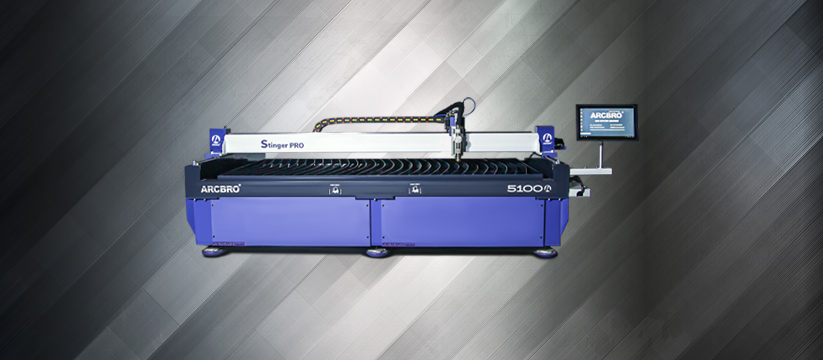

STINGER PRO 5100

CNC High Definition Plasma Cutting Table for Workshop PRO!

It meet all the requirements of HD cutting, improve production efficiency, reduce operating costs, comprehensively upgrade the cutting process, and build for all-day production. This one perfect plasma machine for every professional workshop own.

- Main frame and crossbeam are heat treated. Machine body strength and durability are maximized.

- High loaded iron gasket, guarantee machine leveling and absorb resonance.

- Fork lift position was already setup, easy to move.

- Magnetic anti-collision torch holder, connected by wire-rope, provide best torch protection.

- Plasma cutting for HD true hole.

- Cutting table is separated from machine frame. If cutting table is damaged by long time use, machine body get no any deformation.

- 21’’ industrial touch screen, best operation experience.

A common thread in the technological advancement of plasma cutting since its invention is the continuous reduction in the cost per foot or meter of metal cut. This phenomenon, greatly accelerated in Stinger pro, is a primary driver of improved profitability for the user.

The cutting speed is three times than flame cutting, but the unit cutting cost is only 1/3 of the laser and same as flame cutting. Such high efficiency and low cost is what all users dream of. Right now, Stinger pro is the best choice to achieve this kind of requirement.

Metal heat treatment is one of the important processes in mechanical manufacturing, which is characterized by improving the inherent quality of the workpiece, which is generally not visible to the naked eye. In order to maximize the service life, every set of Stinger Pro got heat-treated. In this way, we can increase the durability, so that a five years’ working life is promised. Powerful plasma power challenges the strength and accuracy of the airframe. But Stinger Pro performed perfectly.

To be more convenient, Stinger Pro has plug and play design. The operation data, wiring works and mechanism are all done before shipment. So, when you receive it, you can run it.

- SPECS

- DATA SHEETS

Cutting mode | High definition plasma cutting |

Input Voltage | 110V / 220V |

Frequency | 50 / 60Hz |

Cutting size | 3000 * 1500 mm |

Input power | 3600w |

Drive motor | Panasonic servo motor |

Reducer | 1:25 |

CNC controller | IPC |

Plasma Power Source | ArcBlitz HD |

Running Cutting Speed | 0 – 20000 mm/min |

Tolerance | ≤ 0.3mm |

Height Control | Automatic voltage THC |

ArcBro’s Community is a very DYNAMIC and FREE communication community which is composed of Metal Workers with many years experiences, professional cutting ENGINEERS, and ArcBro’s LOYAL CUSTOMERS.

You can feel free to communicate and discuss all issues about all cutting questions and problems, learn more cutting tips. The engineer team will reply all the time!

STILL HAVE QUESTIONS? CONTACT US NOW!

CHOOSE A PRODUCTS

Choose the one that best meets you in all range of ArcBro professional CNC cutter!

LEARNING CAMPUS

View ARCBRO learn campus online to learn the machines before you get them.