Super Useful Tips To Improve CNC Cutting Machine

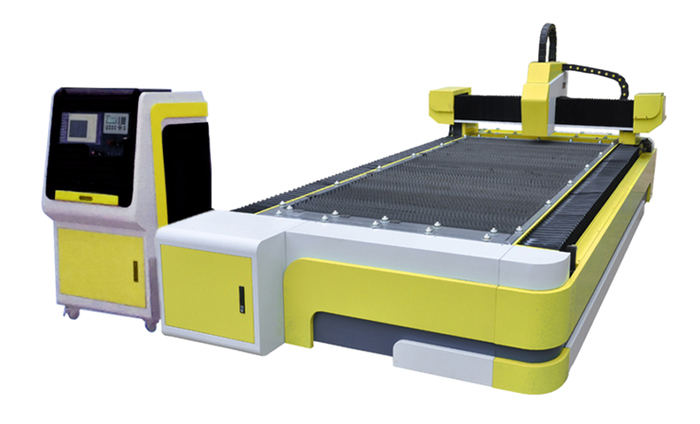

CNC machines are electro-mechanical devices that manipulate machine using computer programming inputs. CNC cutting machine, on the other hand, is a high quality machines used to cut tables, furniture and materials with high thickness. The operators of the CNC machine include the men and women who design and make cabinets, woodwork, signs, and a whole range of metal, solid surface and plastic objects.

The machine interprets the design as instructions for cutting prototype parts. The operators of cutting CNC machine understands the various skills as those possessed by various traditional craftsmen. The ability to program computer devices to control machine tools rapidly advances shop productivity by automating the highly technical and labor intensive processes. Thus, it is a machine which makes sure of the minute details and makes sure that the finishing can be great.

A quality CNC machine has a cutting table that covers the area bounded by a length of four feet and a width of eight feet. Also, the table must handle a standard 4 x 8 plate of metal, wood, plastic, glass, or stone. In case the table that lacks the sufficient length or width, it will make the work rigorous and the operator have to repeatedly reposition the plate. Operators of the CNC cutting machine refer to such repositioning as indexing.

The selection of the cutting CNC machine is primarily determined by the nature of cutting that will be performed by the machine operator. The cutting machine must perform bevel cutting as it allows the operator to trim, reduce, shave, and pare the material in the plate. The other aspect to consider is that both types of cutting will subject to a fair amount of wear and tear. Therefore, you need to purchase a machine with adequate customer support. Such support should include the availability of spare parts and an absence of spare parts could require the electronics of the machine.

The manufacturers who employ these operators know how important it is to have a good quality CNC cutting machine. A good basic cutting machine does both plasma and oxyfuel cutting. Other modifications on a CNC machine might be directed at installation of the equipment for laser or water jet cutting. Refinements on a basic cutting machine might provide it with the ability to perform other functions, functions such as:

· Spotting holes for drilling

· Drilling aluminum

· Cutting a shape in the sides or end of tubing

· Routing wooden shapes

The requirement of retrofitting would deprive the operator of production time. It would diminish the quantity of goods and decrease in the amount of time the operator will be spending at the machine. The operator of a CNC machine needs to spend a large percent of time indexing will not have much time to spend on the actual cutting. Thus, the need for operators to spend time indexing can prove a detriment.

Most of these technologies are highly specialized and are used in special cases for mass-production involving a particular type of material. In case you opt for the automated versions of the CNC cutting machine, it improves both the speed and the accuracy with which prototype parts can be created.