CNC (Computer Numerical Control) cutting machines have revolutionized the manufacturing industry by offering precision, speed, and versatility. These advanced machines automate the cutting process, allowing businesses to produce complex parts and designs with high accuracy. In this blog post, we will explore what CNC cutting machines are, the different types available, their benefits, and the industries they serve.

What is a CNC Cutting Machine?

A CNC cutting machine is a tool that uses computer software to control its movements and cutting actions. These machines can cut, shape, and carve materials like metal, wood, plastics, and composites with great precision. The operator inputs a digital design file into the machine, and the CNC machine follows the instructions to cut or engrave the material.

Types of CNC Cutting Machines

There are various types of CNC cutting machines, each suited for different applications and materials. Here are some of the most commonly used:

CNC Laser Cutting Machine

Laser cutting machines use a focused laser beam to cut through materials. These machines provide extremely fine cuts and are ideal for thin materials.

- Benefits: High precision, smooth edges, minimal material waste.

- Applications: Metal fabrication, signage, jewelry making.

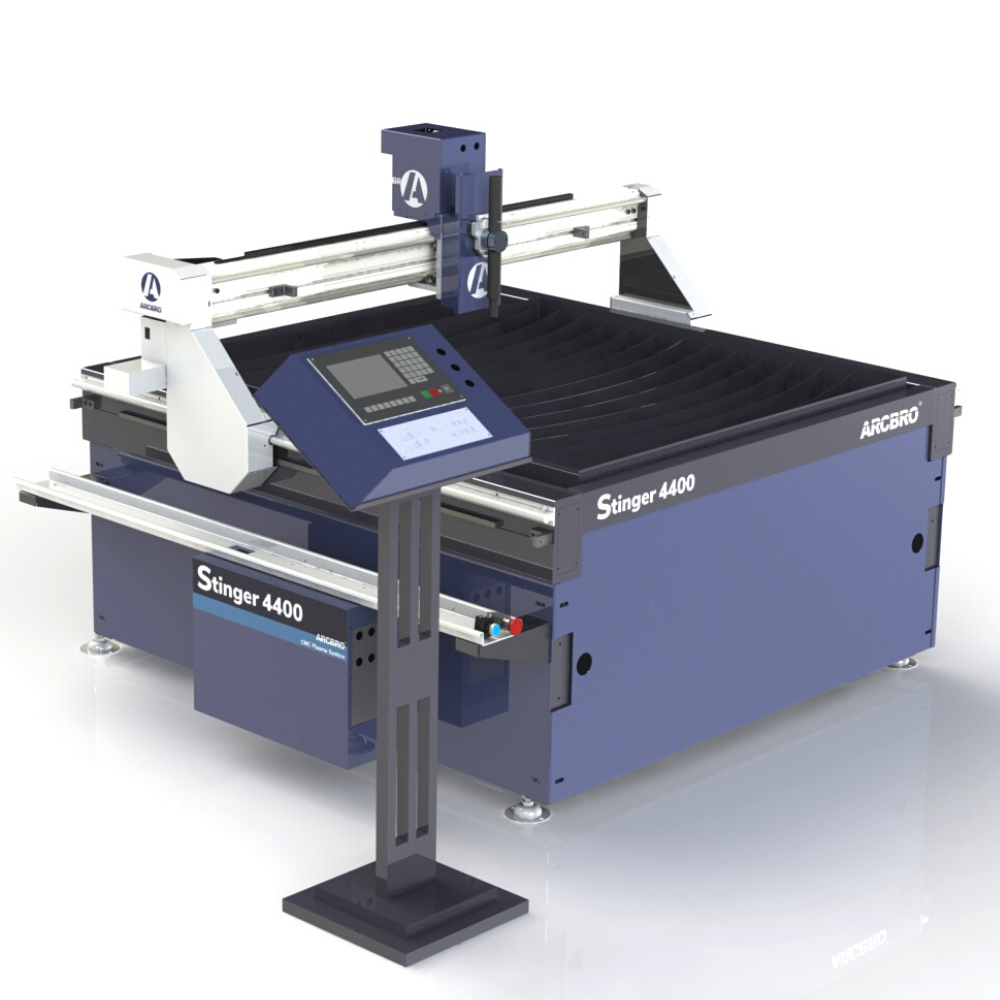

CNC Plasma Cutting Machine

Plasma cutting machines use ionized gas to cut through metal. These machines are faster than laser cutting machines and are often used for cutting thicker materials.

- Benefits: Faster cutting speed, cost-effective for thick materials.

- Applications: Heavy industries, automotive, and construction.

CNC Water Jet Cutting Machine

Water jet cutting machines use high-pressure water mixed with abrasives to cut through materials. They are suitable for cutting a wide range of materials without generating heat.

- Benefits: No heat-affected zone, precise cutting, and versatile.

- Applications: Aerospace, automotive, and food industry.

CNC Router Cutting Machine

CNC routers are versatile machines that can cut, carve, and mill a variety of materials such as wood, plastics, and soft metals. They are often used for creating intricate designs in materials that are not too thick.

- Benefits: Great for wood and soft material cutting, intricate designs.

- Applications: Furniture making, cabinetry, and signage.

Benefits of Using CNC Cutting Machines

CNC cutting machines offer several advantages over traditional manual cutting methods:

- Precision: CNC machines provide incredibly accurate cuts, ensuring high-quality products with minimal errors.

- Speed: These machines can work much faster than manual tools, increasing production efficiency.

- Consistency: Once a design is programmed, the machine can produce identical cuts repeatedly with no variation.

- Automation: Reduces the need for human intervention, lowering labor costs and minimizing the chance for mistakes.

Applications of CNC Cutting Machines

CNC cutting machines are used across many industries for various applications. Here are a few key sectors:

- Manufacturing: Produces parts and components for machinery, automotive, and electronics.

- Aerospace: Used for cutting complex parts with high precision, often from exotic materials.

- Signage: Ideal for creating custom signs, letters, and logos in various materials.

- Art and Design: Enables intricate designs in materials like wood, acrylic, and metal.

Conclusion

CNC cutting machines have transformed the way products are made by offering superior precision, speed, and efficiency. Whether you need to cut metal, wood, or plastics, there is a CNC cutting machine suited to your needs. From manufacturing to art, these machines are indispensable in producing high-quality, consistent products across various industries. By understanding the different types of CNC cutting machines and their benefits, you can make informed decisions that enhance your production processes.

CNC cutting machine