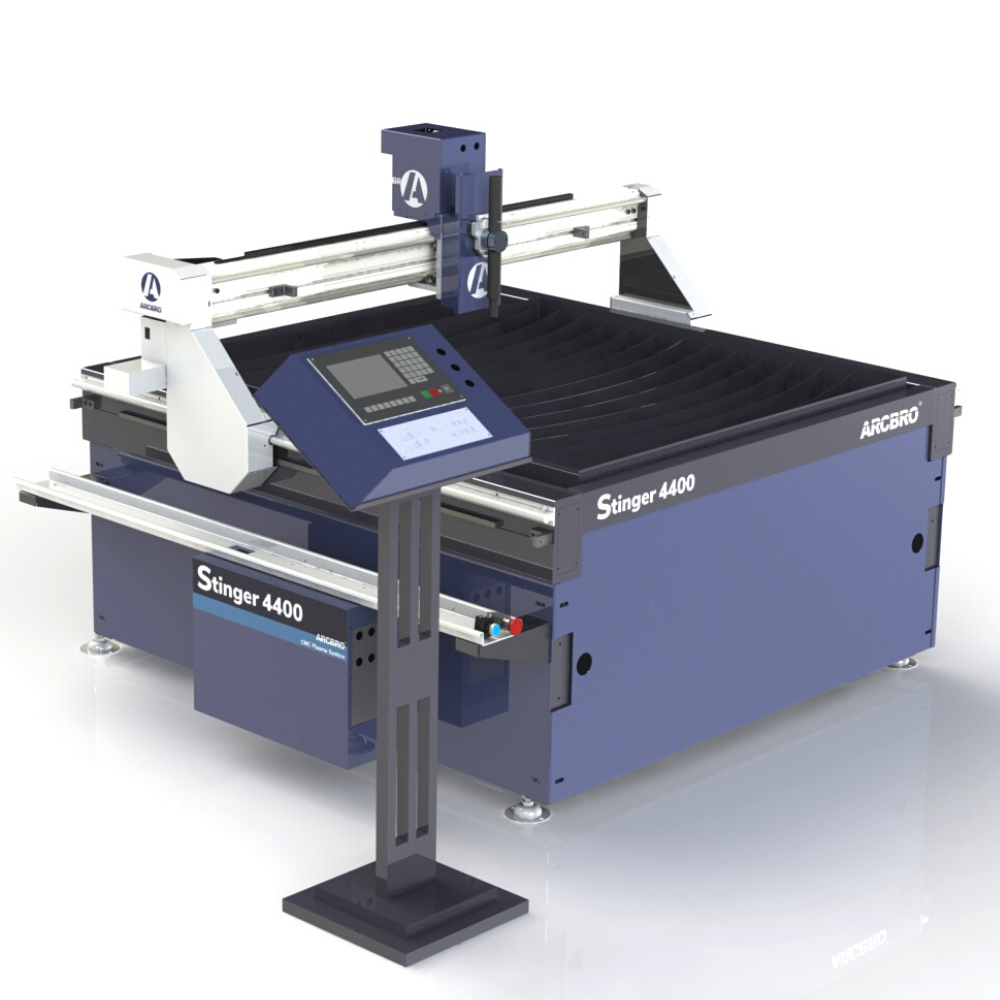

A CNC cutting machine is a computer-controlled device used to cut materials with high precision. These machines are widely used in manufacturing for cutting metals, plastics, and other materials. CNC cutting machines ensure accuracy, efficiency, and consistency in production processes.

Benefits of CNC Cutting Machines

CNC cutting machines offer several advantages, including precise cuts, reduced waste, and increased production speed. They are capable of complex shapes and designs, making them ideal for various industries. These machines enhance productivity by minimizing manual labor and errors.

What Is a Pipe Cutting Machine?

A pipe cutting machine is specifically designed to cut pipes and tubes accurately. These machines can handle different pipe sizes and materials, ensuring clean and precise cuts. Pipe cutting machines are essential in industries like construction, plumbing, and manufacturing.

Uses of Pipe Cutting Machines

Pipe cutting machines are used for cutting pipes to specific lengths and shapes required in various applications. They provide efficient and accurate cuts, reducing material waste and labor costs. These machines are vital for projects requiring precise pipe dimensions and high-quality cuts.

CNC Cutting Machines vs. Pipe Cutting Machines

Both CNC cutting machines and pipe cutting machines are crucial in the manufacturing process. While CNC machines are versatile and can cut various materials, pipe cutting machines are specialized for cutting pipes and tubes. Depending on your needs, you can choose the appropriate machine for your project.

Conclusion

Understanding the roles of CNC cutting machines and pipe cutting machines highlights their importance in manufacturing. These machines offer precision, efficiency, and versatility, making them essential tools in various industries. By investing in high-quality cutting machines, you can enhance your production processes and achieve better results.

CNC cutting machine