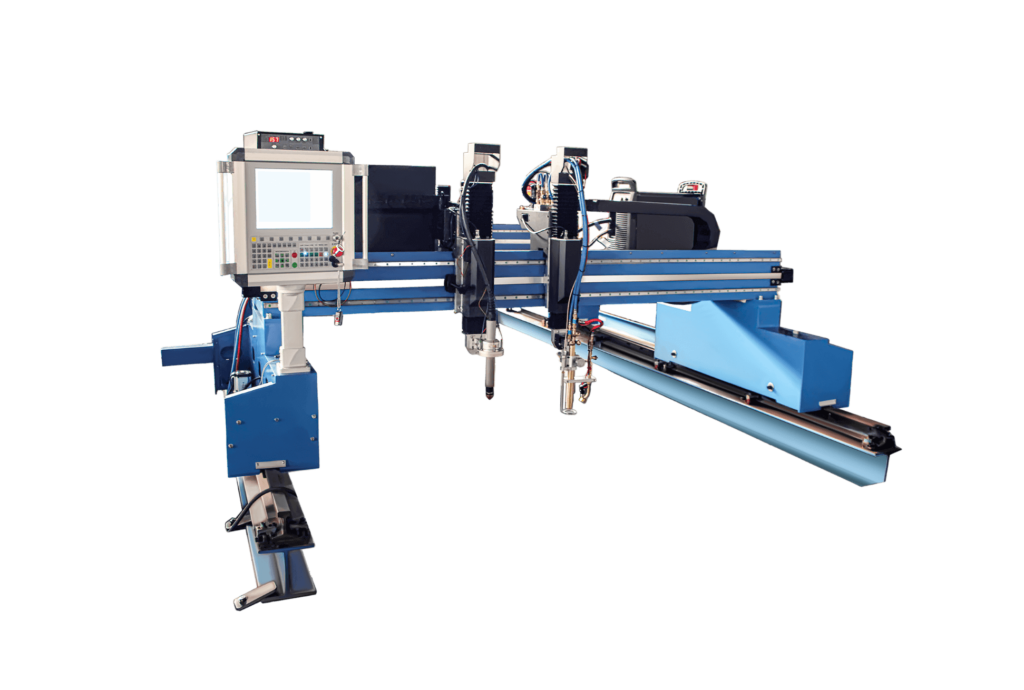

X-PRO

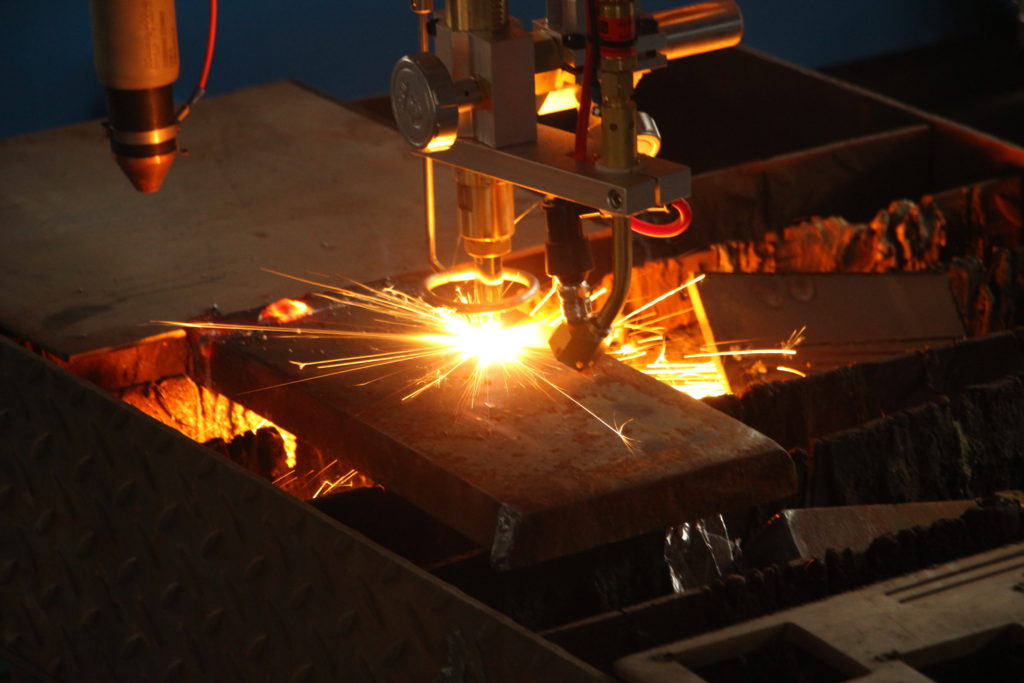

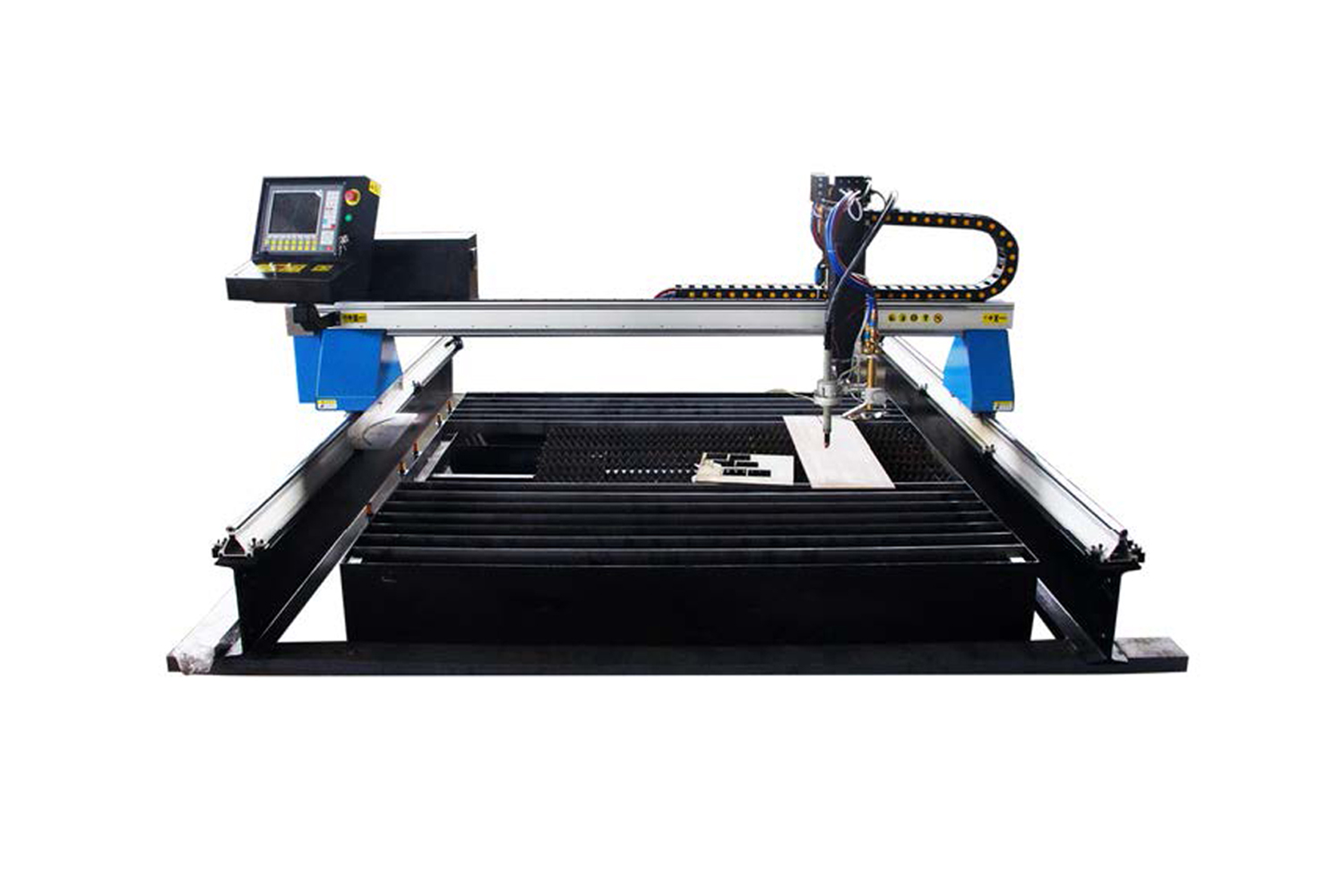

CNC GANTRY PLASMA/FLAME CUTTING MACHINE

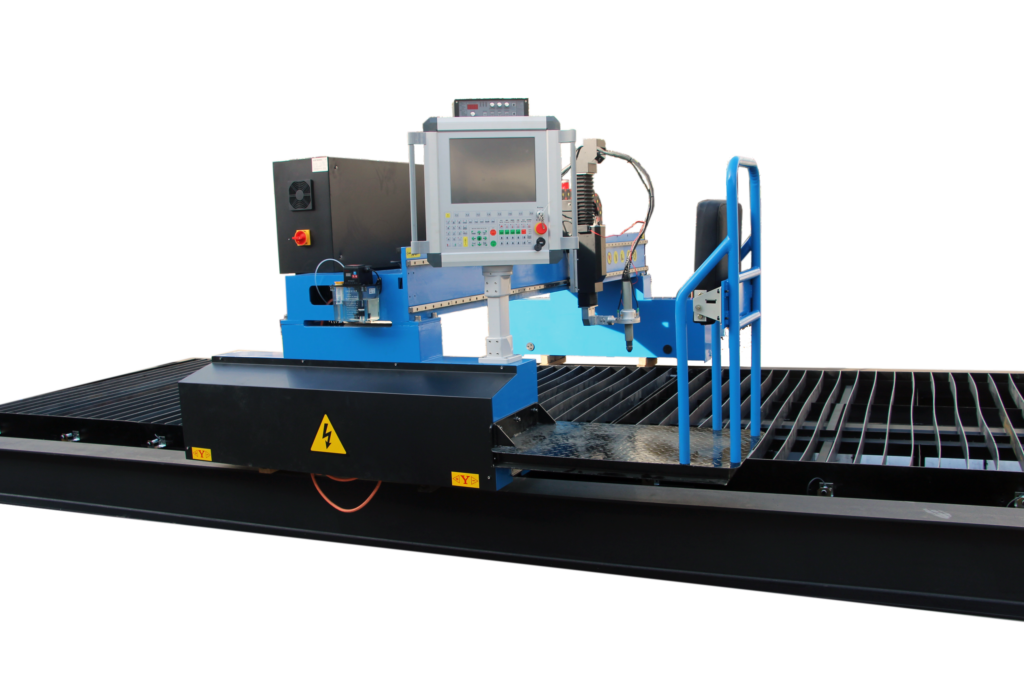

X Pro is a heavy-duty CNC Gantry cutting machine with, dual drive. The new longitudinal welding technology is adopted in Y-axis, extendable as long as you wish. The high precision 24Kg heavy rails is adapted in the X-axis and Y-axis. The high precision rack and pinion are adopted in the X-axis and Y-axis.

The automatic ignition feature is optional, the standard package has one oxy-fuel torch with the motorized driven, the capacitive or the arc voltage THC is optional, to help the customer to realize automatic oxy-fuel and plasma cutting.

It also can greatly help customers improve productivity, support the plasma and flame, Japanese Panasonic servo motor system, high precision, easy operation, absolutely durable. It can import DXF files directly and provides the full range of cutting thicknesses of metal.

Standard Features for common:

- Effective cutting area: 3000*6000mm, can be extended

- Both plasma and flame mode (with Auto-ignition), two moving unit

- Fangling system F2300A

- HYD XPTHC-300-3

- Libellula wizard 3 software

- Panasonic servo motor, dual drive, 450w*3

- Double cylinder guiding rail

- Effective cutting area: 3000*6000mm, can be extended

- Both plasma and flame mode (with Auto-ignition), two moving unit

- HYD IPC HYD XPTHC-300-3

- Libellula wizard Pro software

- Panasonic servo motor, dual drive, 750w*2+400w*1

- Square guiding rail

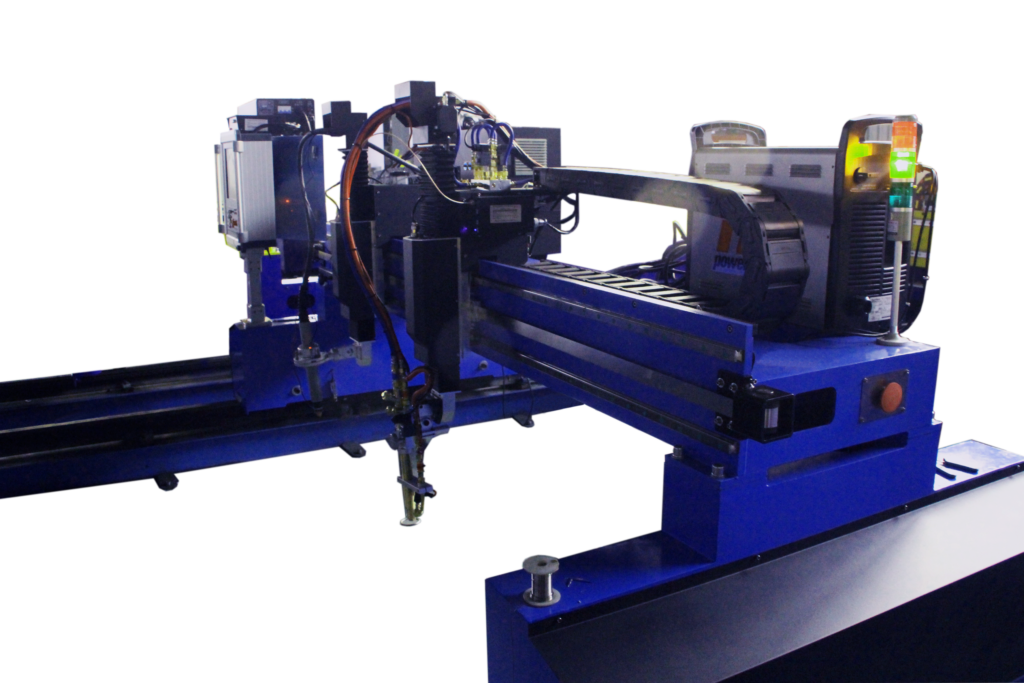

The linear rail is used horizontally and the 24 Kg rail is used in the longitudinal direction, which is high precision and durable. the strong beam can carry plasma power. the large-span trolley design effectively balances the torque of the equipment. Reduce the error caused by inertia. When using multiple lifting bodies, connect them with stainless steel belts to adjust the distance between the two lifting bodies and make the cutting mode change quickly.

The strong beam can carry the plasma power source.

The large-span trolley design effectively balances the torque of the equipment.

Reduce the error caused by inertia.

- SPECS

- DATA SHEETS

| Type | X Pro |

| Input Voltage | 110V/220V |

| Cutting Mode | Flame and Plasma |

| Cutting Torch No. | 1 group Flame and Plasma both standard, can be multi torches |

| Driving Mode | 750W x 2, 400w x 1, AC Panasonic servo system(optional), Dual driving mode |

| Height Control | Auto height controller for Flame and plasma torch |

| Flame Cutting Thickness | 6~300mm |

| Plasma Cutting Thickness | Due to the plasma power source |

| Flame Cutting Speed | 0-1,000mm/min |

| Plasma Cutting Speed | 0-9.000mm/min |

| Display | LCD 10″Touch Screen |

| Nesting software | Libellula |

| Options | Capacitance Auto Torch Height Control(THC)and anti-collision |

| Cutting Gas | Flame: (Acetylene, Propane or Liquid Gas)+ Oxygen |

| Tolerance | <0.2mm |

ArcBro’s Community is a very DYNAMIC and FREE communication community which is composed of Metal Workers with many years experiences, professional cutting ENGINEERS, and ArcBro’s LOYAL CUSTOMERS.

You can feel free to communicate and discuss all issues about all cutting questions and problems, learn more cutting tips. The engineer team will reply all the time!

STILL HAVE QUESTIONS? CONTACT US NOW!

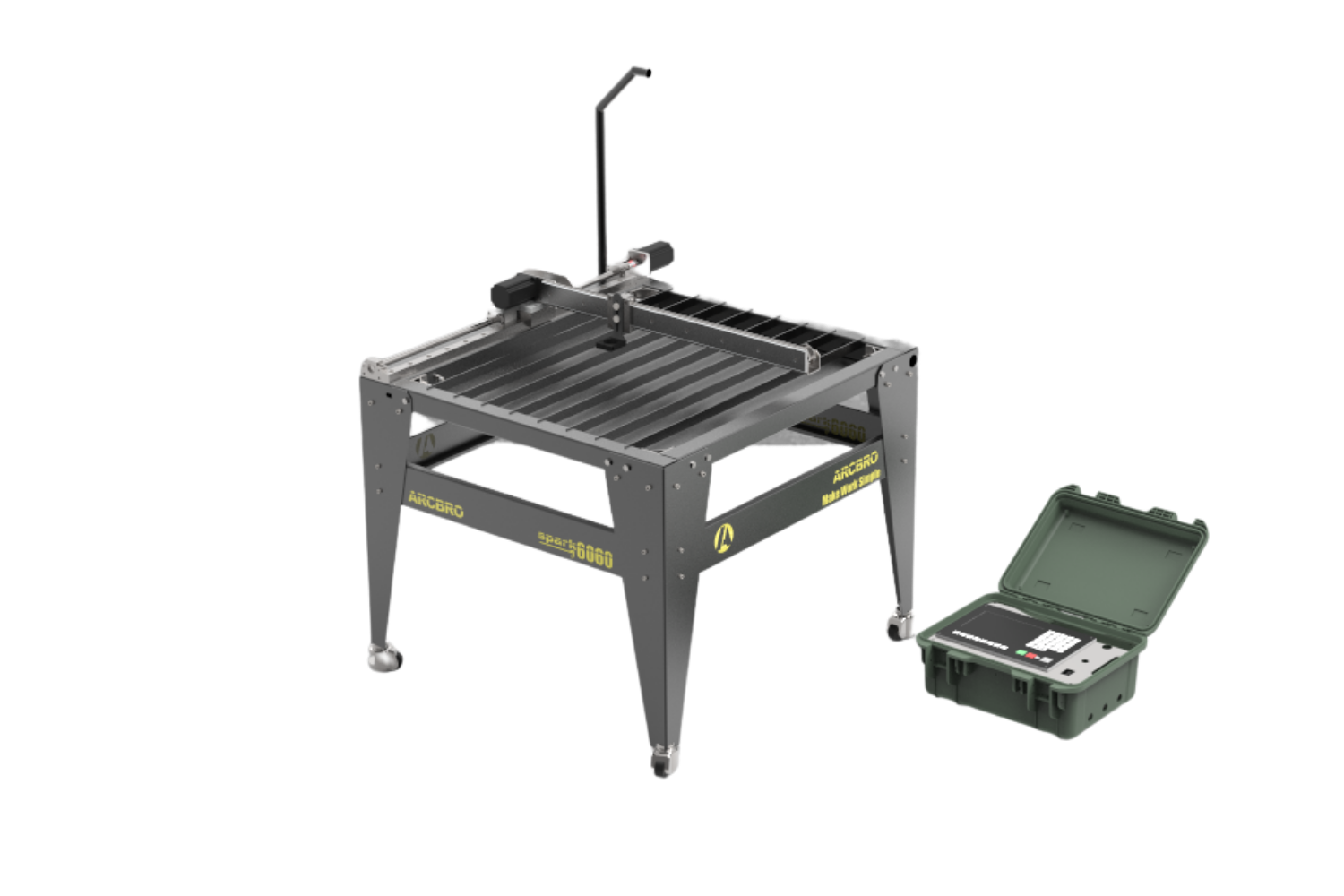

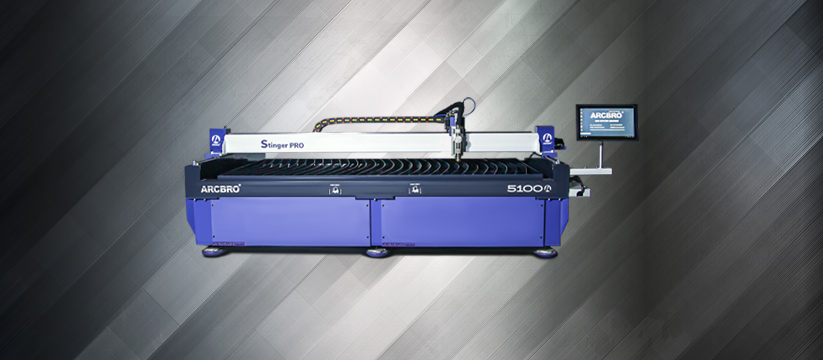

CHOOSE A PRODUCTS

Choose the one that best meets you in all range of ArcBro professional CNC cutter!

LEARNING CAMPUS

View ARCBRO learn campus online to learn the machines before you get them.